Bari mu ga yadda yake aiki:

Whula neLatsa-fit?

Latsa-fit shine tsangwama tsakanin sassa biyu wanda aka tilasta wa sashi a ƙarƙashin matsin lamba zuwa cikin ɗan ƙaramin rami a ɗayan.

A zahiri, nau'in tsangwama ce ta dace.

Ana amfani da fasahar dacewa da latsa ko'ina, kuma haɗin kan PCB ɗaya ne daga cikin aikace-aikacen sa na yau da kullun.

Lokacin da ake siffantawa cikin Sinanci, yawanci muna amfani da kalmomi daban-daban kamar su kutsawa, daɗaɗɗen latsawa, da kutsawa.Yawancin lokaci ana amfani da masana'antar don yin amfani da "Latsa Fit" kai tsaye don bayyanawa.Babban abin da ke mayar da hankali kan wannan labarin kuma shine aikace-aikacen dacewa da latsawa a cikin masana'antar PCB (yawan fitattun fitattun latsawa da yawa).

Menene fa'idodin buga jarida?

Babban hanyoyin shigar sassa akan PCB sune walda da latsa fit.Bari mu kwatanta fa'idodi da rashin amfanin waɗannan hanyoyin haɗin gwiwa guda biyu tare da wasu bayanan al'ada.

| Sayarwa | Latsa-fit | |

| cin abinci | 30-40 kW | 4-6 kW |

| muhalli | Welding iska da wurin zama | Babu wurin zama |

| farashi | Bukatar PA, PPS | Babu matsala na tanadin zafin jiki, yi amfani da kayan ƙananan farashi kamar PBT, PET da dai sauransu. |

| Kayan aiki | Babban jari da kuma babban farashin yanki | Ƙananan zuba jari da ƙananan yanki |

| Akwai sarari | 5-15 mm | 2mm ku |

| Ƙimar rashin ƙarfi | 0.05 daidai | 0.005 daidai |

Daga bayanan kwatancen, zamu iya ganin cewa Latsa Fit shine mafi kyawun hanyar haɗin PCB fiye da walda dangane da wasu alamun aiki.Tabbas, walda ba ta da amfani, in ba haka ba ba za a sami wuraren walda da yawa akan PCB ba.Misali, walda yawanci yana da mafi girman juriya ga juriyar juzu'i na fil, kuma haɗin walda ya fi karko, Koyaya, Latsa Fit ya fi kyau a cikin alamun fasali da yawa.

Hanyoyin ƙira na yau da kullun na Jarida

Kafin gabatar da hanyar ƙira, ya zama dole a gabatar da kalmomi guda biyu da aka saba amfani da su:

PTH: Plated ta Hole

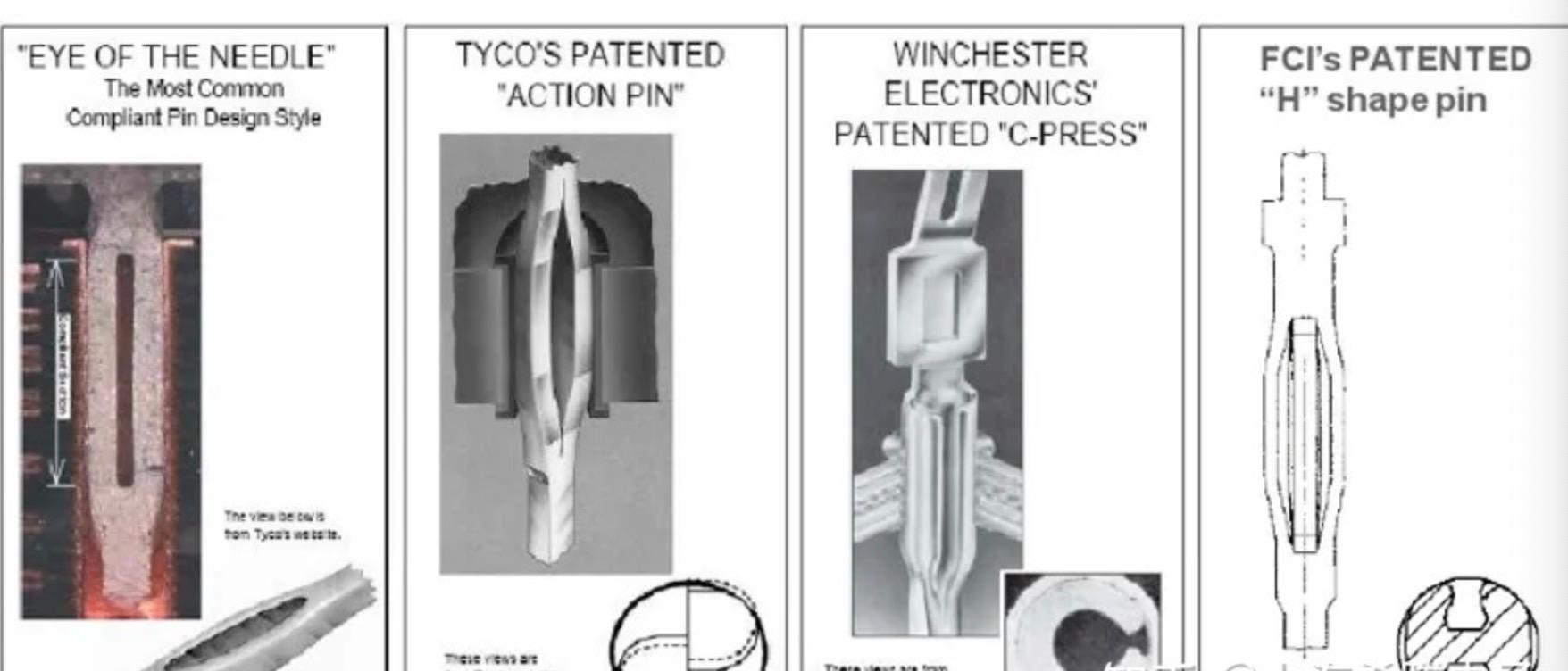

EON: Idon Allura

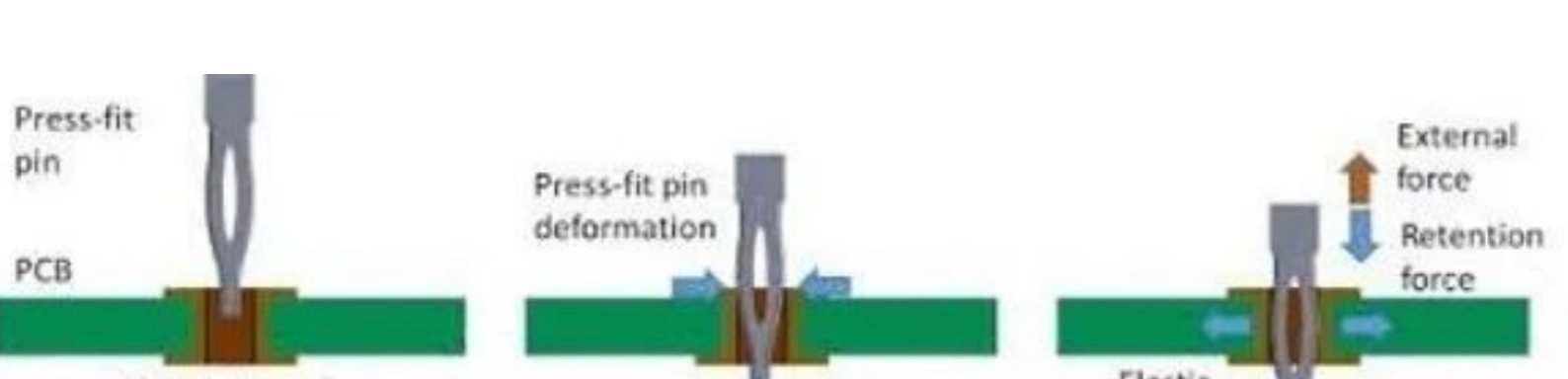

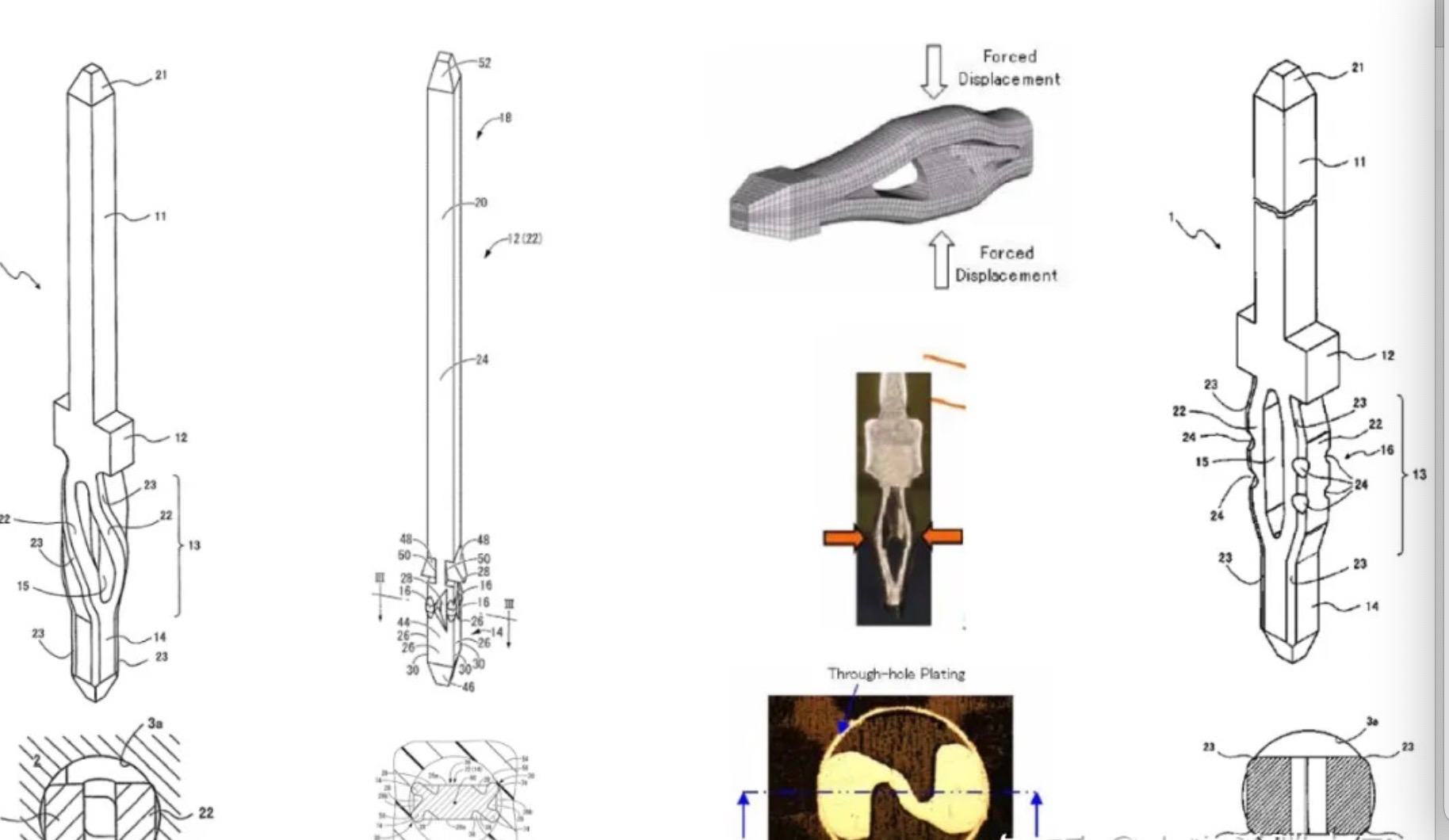

A halin yanzu, fitilun da aka yi amfani da su a kan Fitar Latsa na asali ne na roba, wanda kuma aka sani da fil masu yarda, waɗanda gabaɗaya sun fi girma a diamita fiye da PTH.A lokacin tsarin taro, sassan allura za su zama nakasu, wanda zai haifar da haɗin haɗin gwiwa tare da m PTH.Idan aka kwatanta da ƙaƙƙarfan allura, allurar da ta dace na iya ba da izinin jurewar PTH mafi girma.

A hankali alluran ramin fil ya zama babban abin da ke faruwa a kasuwa.Yana da sauƙi a cikin ƙira kuma ana iya amfani dashi tare da buɗaɗɗen haƙƙin mallaka.Ko da ba ya buƙatar ƙoƙarin ƙira da yawa, ana iya amfani da shi tare da shirye-shiryen ƙirar ƙira, waɗanda ke da halayen ƙarancin shigar da ƙarfi da ƙarfin riƙewa.

Hoton da ke sama yana nuna tsarin fil/tasha gama gari da yawa.Na farko shine tsarin ƙira na yau da kullun.Mahimman tsarin ƙirar pinhole yana da sauƙi a cikin tsari, amma yana buƙatar babban tsari da wuri;Na biyu shine samfurin haƙƙin mallaka na Kamfanin TE.Dangane da tsarin pinhole, yana da ɗan ƙaramin kusurwar juyawa, wanda zai iya dacewa da ramuka daban-daban.Duk da haka, yana da buƙatu mafi girma don diamita na rami, kuma zai haifar da wani ƙarfin juyawa akan ramin;Na uku shine Winchester Electronics' na baya ikon mallakar "C-PRESS", wanda ke da siffa C daga sashin giciye.Abubuwan da ake amfani da su shine cewa ƙarfin matsawa yana ci gaba da ci gaba, lalacewar PTH ƙananan ƙananan ne, kuma rashin amfani shine PTH tare da ƙananan budewa yana da wuya a cimma;Na ƙarshe shine nau'in lambar tuntuɓar H na Kamfanin FCI.Amfanin shi ne cewa yana da sauƙin sarrafawa lokacin da ake yin crimping, amma rashin amfanin shi ne cewa yana da wahala a kera fil ɗin lamba.

Common kayan da kuma masana'antu tsari

Abubuwan gama gari na Pin sun haɗa da tagulla na kwano (CuSn4, CuSn6), tagulla (CuZn), da farin jan ƙarfe (CuNiSi), daga cikinsu akwai farin jan ƙarfe yana da ƙarfin aiki, kuma zafin amfani na iya wuce 150 ℃;An rufe murfin gabaɗaya ta hanyar sakawa na lantarki ko zafi tsoma μ m+1 μ M na Ni + Sn, SnAg ko SnPb, da sauransu. matsi mai ƙarfi da babban ƙarfin riƙewa a ƙarƙashin yanayin masana'anta mai sauƙi da ƙarancin farashi.

Abubuwan da aka saba amfani da su na PTH shine gilashin fiber + epoxy resin + foil jan karfe, tare da kauri> 1.6, kuma rufin shine gabaɗaya tin ko OSP.Tsarin PTH yana da sauƙin sauƙi.Kullum magana, adadin PCB yadudduka ya fi 4. Buɗewar PTH gabaɗaya mai tsauri ne, kuma takamaiman buƙatun sun dogara da ƙirar Pin.Gabaɗaya, kauri na platin jan karfe yana kusan 30-55 μm.Kaurin jigon kwano shine gabaɗaya> 1 μm.

Analysis na latsa fit/fitar da tsari

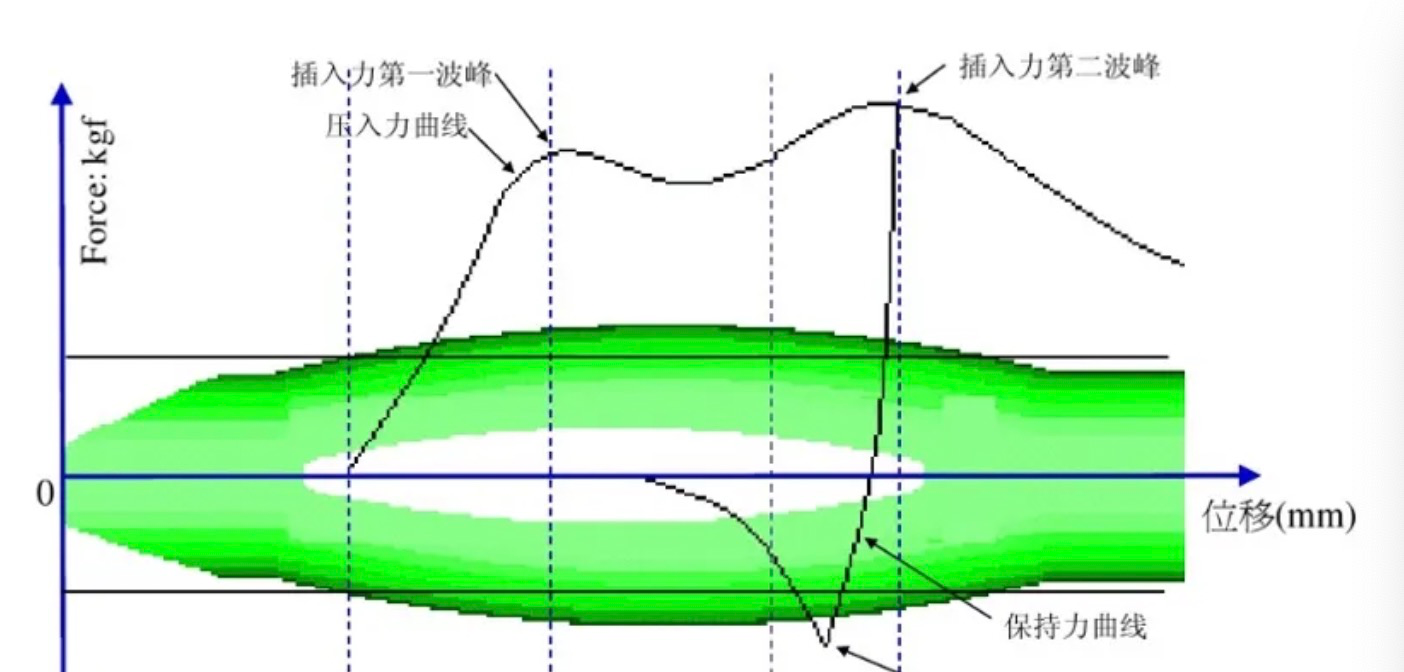

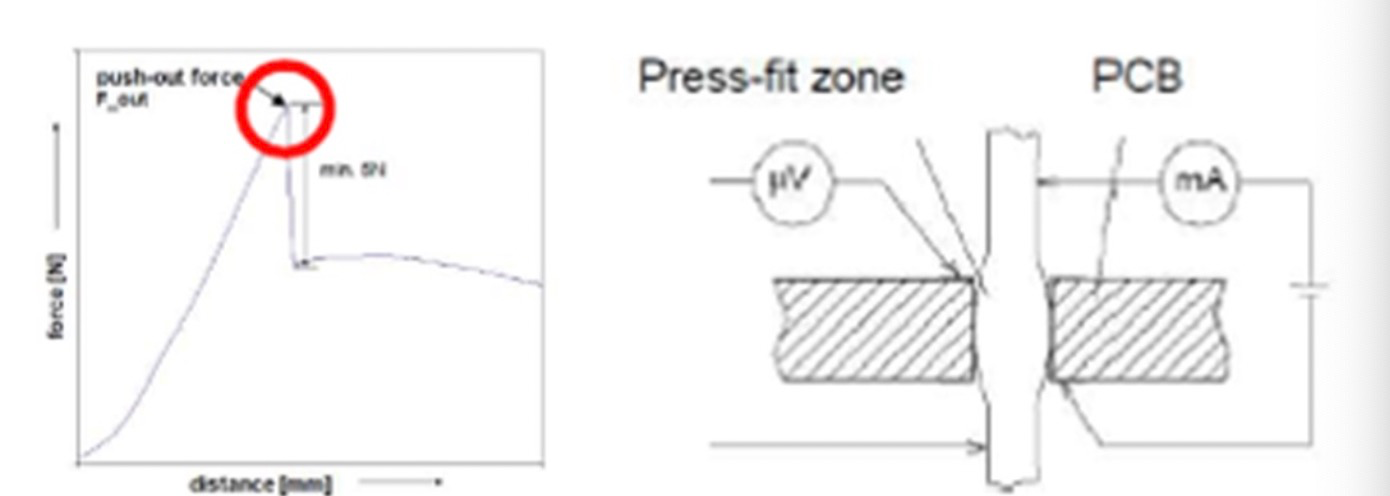

Ɗaukar tsarin fitilun da aka fi sani da shi a matsayin misali, kamar yadda aka nuna a hoton da ke ƙasa, akwai canjin yanayin matsa lamba a cikin dukkan tsarin latsawa da cirewa, wanda kuma yana da alaƙa da tsarin tsarin Pin.

Latsa cikin tsari:

1. An saka fil a cikin rami, kuma tip ya shiga ba tare da nakasawa ba

2. Fin ya fara latsawa, EON ya fara lalacewa, kuma farkon ƙoƙon kalaman yana bayyana a cikin tsarin latsawa.

3. Fin yana ci gaba da dannawa, EON a zahiri ba shi da ƙarin nakasawa, kuma ƙarfin latsawa yana raguwa kaɗan

4. Fin yana ci gaba da danna ƙasa, yana haifar da ƙarin nakasawa, da tsayin kalaman na biyu

Ya bayyana a cikin aikin latsawa

A cikin daƙiƙa 100 bayan an gama aikin latsawa, ƙarfin riƙewa zai ragu da sauri, tare da raguwar kusan 20%.Za a sami bambance-bambance masu dacewa bisa ga ƙirar fil daban-daban;Sa'o'i 24 bayan dacewa da latsawa, an kammala aikin walda mai sanyi na Pin da PTH.

Wannan yana faruwa ne ta hanyar halayen zahiri na ƙarfe, kuma akwai ɗan ƙaramin wuri don ingantawa.Ana iya tabbatar da ko ƙarfin riƙewa na ƙarshe ya cika buƙatun ƙirar samfur ta hanyar gwajin ƙarfin turawa.

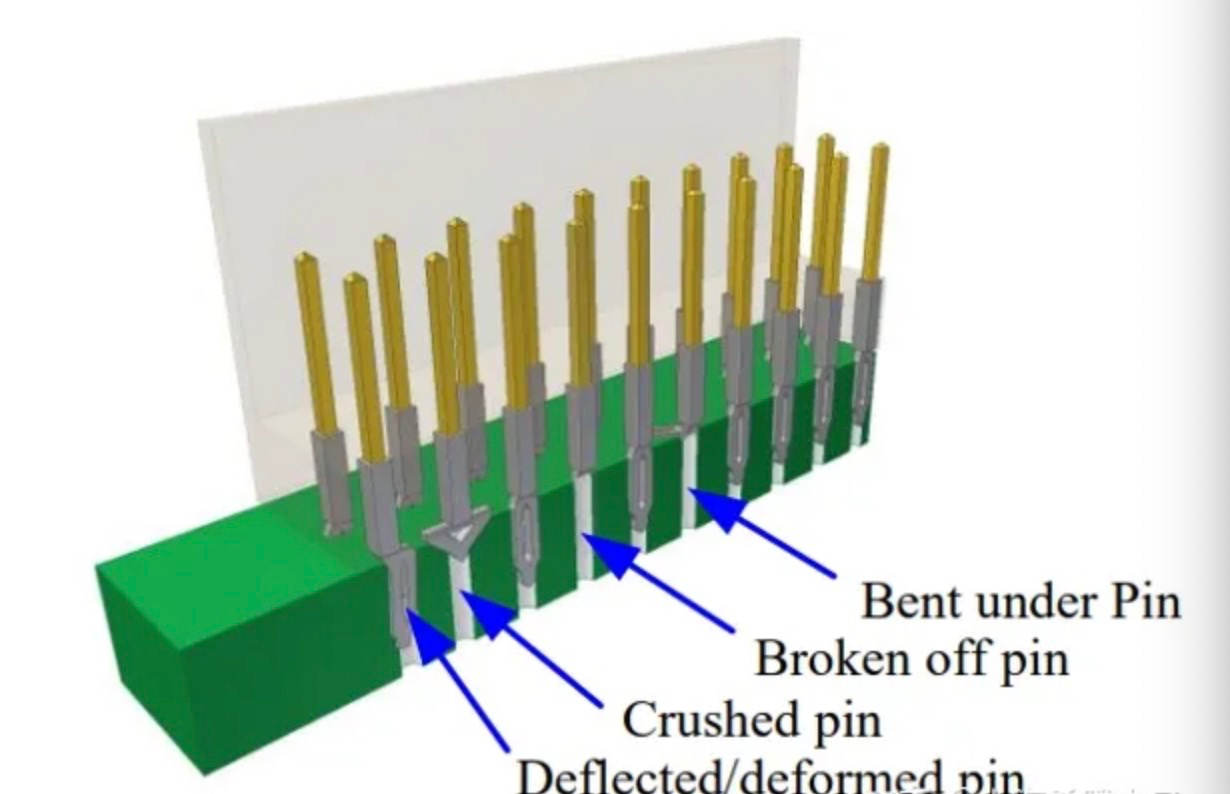

2. Wasu hanyoyin gazawa yayin saka fil

Kamar yadda aka nuna a cikin hoton da ke ƙasa, fil ɗin na iya zama naƙasasshe, niƙasa, niƙasa, karaya da lanƙwasa yayin sakawa.

Waɗannan su ne yuwuwar yanayin gazawar fil ɗin tuntuɓar yayin aikin dacewa da latsawa.Tunda ana buƙatar shigar da fil ɗin lamba a cikin PTH, yana yiwuwa ba za a iya gano shi ta gani ba bayan dannawa, kuma ba za a iya gano lalacewar ƙarfin injin ta hanyar gwajin aikin lantarki ba.

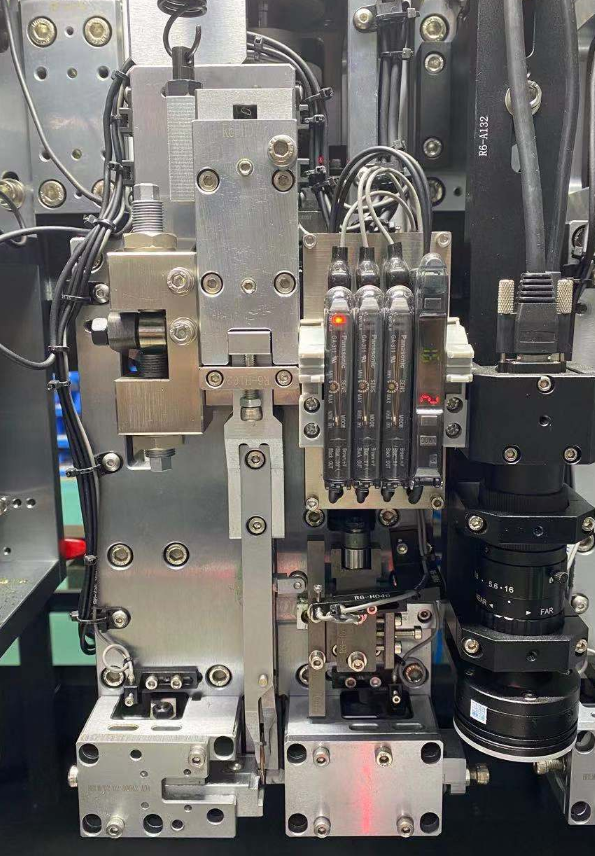

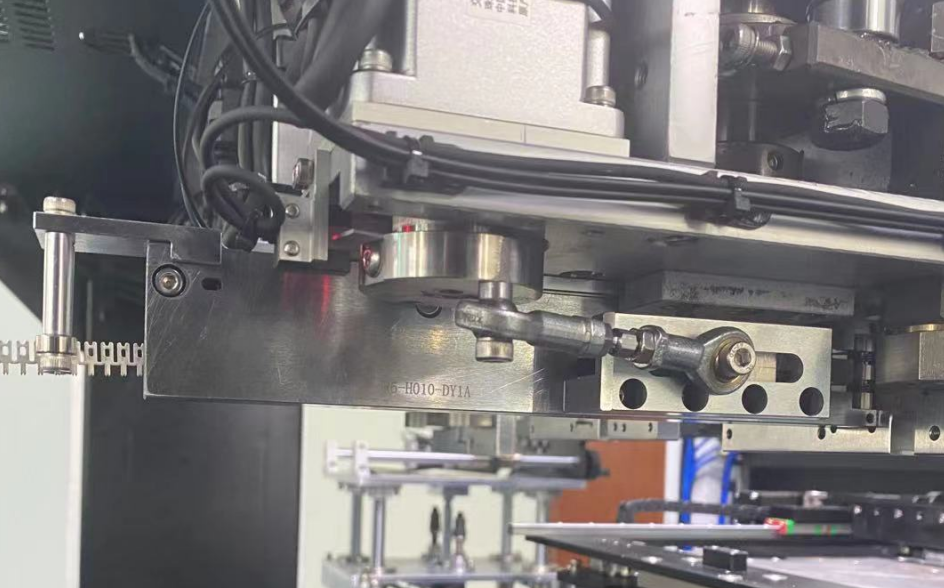

Waɗannan hanyoyin gazawar suna buƙatar kulawa yayin aiwatar da dacewa da latsawa.PROMESS yana ba da hanyar lanƙwasa, taga, matsakaicin da mafi ƙarancin ƙima da sauran hanyoyin sa ido don tabbatar da cewa gabaɗayan tsarin dacewa da latsawa na kowane fil yana iya sarrafawa kuma abin dogaro.Kuna iya sake ganin nunin harka a cikin bidiyon.PROMESS yana ba da madaidaicin madaidaicin, 100% hanyoyin sarrafa tsari don tabbatar da cewa duk samfuran da ke barin masana'anta ba su da samfuran lahani, Hakanan sarrafa tsarin na iya rage sharar masana'antu na kwamitin PCB zuwa wani yanki kuma rage farashin samarwa.

3. Gajeren kewayawa

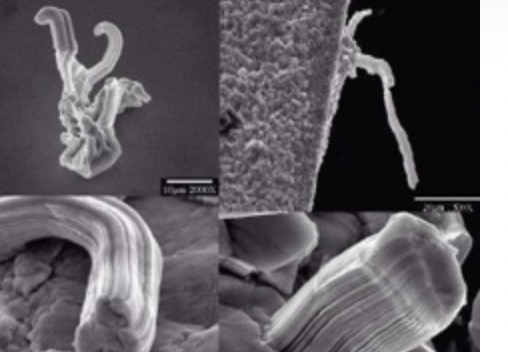

A saman tin mai tsabta, damuwa zai inganta haɓakar tin Whisker, wanda zai haifar da gajeren da'irar da'irar a kan bugu na da'irar, don haka yin haɗari ga aikin module.Sharuɗɗan ƙira don rage haɓakar busassun gwangwani sun haɗa da rage ƙarfin shigar da rage kauri daga saman tin.

Kayan shafawa na yau da kullun na PTH sun haɗa da jan karfe, azurfa, tin, da sauransu

Yadda za a magance matsalar tin whiskers?

A lokacin latsawa, ƙarfin matsawa ba zai zama babba ba, wanda shine sarrafa tsarin latsawa.Bayan dannawa, za'a iya gudanar da gwajin samfurin, kuma za a kula da tin whisker na tsawon makonni 12.

4. Buɗe kewaye

Tasirin Jet/jawo ƙasa:

Yayin aiwatar da latsawa a Fin, allon da'irar da aka buga na iya lalacewa ta hanyar inji.Idan juzu'in ya yi girma sosai, za a tozarta saman allon kewayawa, juzu'in za ta karu, kuma a ƙarshe za a fitar da PTH ta hanyar lokaci.Rage matsa lamba kuma zai iya guje wa tasirin jet.

Tasirin farar fata/delaminate:

Yayin hawan latsa, kowane tsarin Layer na allon da'irar da aka buga za a matse shi.Idan ƙarfin da aka yi amfani da shi ya yi girma da yawa ko PTH ba ta da ƙarfi, ana iya lalata allon da'irar da aka buga.Bayan wani lokaci, danshi zai shiga cikin tsagewar da'irar da aka buga, wanda zai haifar da raguwar aikin keɓewa

Ana iya sarrafa waɗannan matsalolin guda biyu zuwa ɗan lokaci yayin aikin dacewa da latsawa ta hanyar sarrafa ƙarfin latsawa.Bayan an gama dacewa da latsawa, ana kuma iya bincika samfurin ta hanyar gwajin juriya na lamba da ƙididdigar ƙarfe.Ana iya amfani da gwajin juriya na lamba azaman abin gwaji na yau da kullun, kuma ƙididdigar ƙarfe da kanta tana lalata samfurin, don haka ana iya gudanar da gwajin samfur na yau da kullun.

Hannun gwajin amincin samfuran gama gari

Ɗayan hanyoyin gano gama gari shine gwajin tsufa kuma ɗayan shine gwajin halayen haɗin gwiwa

Tsufa shine a kwaikwayi jihar bayan dogon lokacin amfani da kayan gwaji.Hanyoyin tsufa na gama gari sun haɗa da:

1. Dumi ruwa: - 40 ℃ ~ 60 ℃, ci gaba da canji na 30 minutes

2. Babban zafin jiki: 125 ℃, 250 hours

3. Tsarin yanayi: 16 hours high zafin jiki → 24 hours zafi da danshi → 2 hours low zazzabi →

4. Vibration

5. Lalacewar iskar gas: kwanaki 10, H2S, SO2

Gwajin shine don gwada ƙarfin turawa da aikin lantarki.

Hanyoyin gama gari sun haɗa da:

1. Tura ƙarfi (ƙarfin riƙewa): > 20N (bisa ga buƙatun ƙirar samfur)

2. Juriya na lamba: < 0.5 Ω (bisa ga buƙatun ƙirar samfur)

Lokacin aikawa: Nuwamba-10-2022

Youtube

Youtube