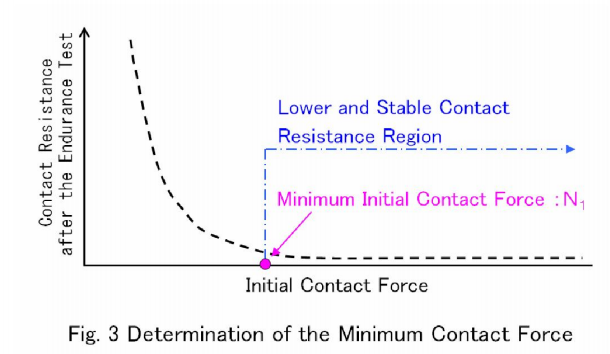

A. Takaitaccen Bayani

Ƙayyadaddun mahaɗan latsa-fit da muka haɓaka shine

taƙaice a cikin Table II.

A cikin Table II, "Girman" yana nufin faɗin lamba na namiji (abin da ake kira "Girman Tab") a mm.

B. Daidaita Ƙaddamar Ƙarfin Tuntuɓar Ƙaddamarwa

A matsayin mataki na farko na ƙirar tasha-fit, dole ne mu

ƙayyade iyakar ƙarfin lamba da ya dace.

A saboda wannan dalili, nakasawa halayen zane-zane na

Ana zana tashoshi da ramuka cikin tsari, kamar yadda aka nuna

a cikin siffa 2. An nuna cewa dakarun tuntuɓar suna cikin axis a tsaye,

yayin da m girma da kuma ta-rami diamita ne a cikin

axis a kwance bi da bi.

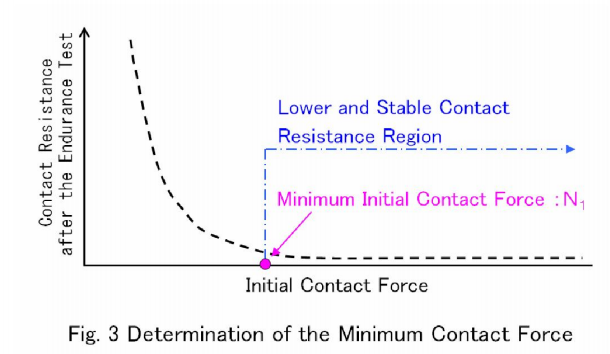

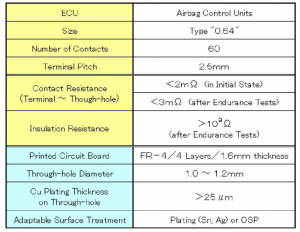

C. Ƙaddamar Ƙaddamar Ƙarfin Tuntuɓi

An ƙayyade mafi ƙarancin ƙarfin tuntuɓar ta (1)

yin makircin juriya na lamba da aka samu bayan jimiri

gwaje-gwaje a cikin axis a tsaye da ƙarfin tuntuɓar farko a kwance

axis, kamar yadda aka nuna a hoto 3 schematically, da (2) gano

mafi ƙarancin ƙarfin tuntuɓar sadarwa don tabbatar da juriyar kasancewa

ƙananan kuma mafi kwanciyar hankali.

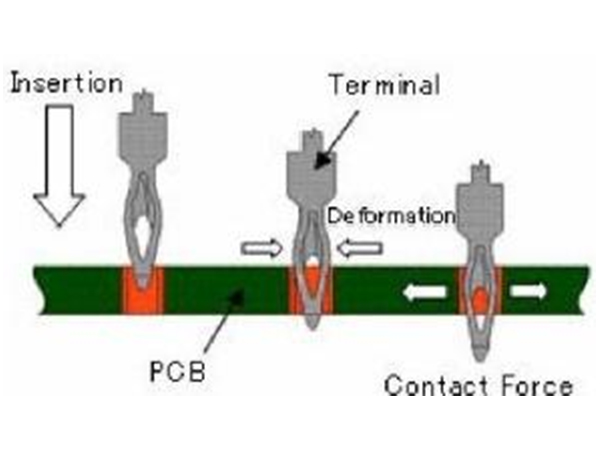

Yana da wahala a auna ƙarfin tuntuɓar kai tsaye don haɗin dacewa da manema labarai a aikace, don haka mun same shi kamar haka:

(1) Saka tashoshi a cikin ramuka, wanda ke da

daban-daban diamita fiye da kayyade iyaka.

(2) Auna nisa tasha bayan shigarwa daga

giciye sashe yanke samfurin (misali, duba siffa 10).

(3) Mayar da faɗin tasha da aka auna a (2) zuwa cikin

Ƙarfin lamba ta amfani da halayen nakasa

zane na tashar tashar da aka samu a zahiri kamar yadda aka nuna a ciki

Hoto 2.

Layuka biyu na nakasar tasha suna nufin ɗaya don

matsakaicin kuma mafi ƙarancin masu girma na tasha saboda tarwatsewa a ciki

masana'antu tsari bi da bi.

Tebura II Scecification na Haɗin da muka haɓaka

A bayyane yake cewa karfin lamba ya haifar tsakanin

Tashoshi da ko da yake-ramuka ana ba da su ta hanyar mahaɗin biyu

zane-zane na tashoshi da ramuka a cikin siffa 2, wanda

yana nufin daidaitaccen yanayin matsawa ta ƙarshe kuma ta hanyar fadada rami.

Mun ƙaddara (1) mafi ƙarancin ƙarfin lamba

da ake buƙata don yin juriya na lamba tsakanin tashoshi da

ko da yake-ramuka ƙananan kuma mafi kwanciyar hankali kafin / bayan jimiri

gwaje-gwaje don haɗuwa da ƙananan ƙananan masu girma da kuma

matsakaicin diamita ta rami, da (2) matsakaicin ƙarfi

isa don tabbatar da juriya na rufi tsakanin maƙwabta

ta-ramuka sun wuce ƙayyadaddun ƙimar (109Q don wannan

ci gaba) bin gwajin haƙuri don

hade da matsakaicin matsakaicin girma da m

diamita ta rami, inda lalacewa a cikin rufi

juriya yana faruwa ne sakamakon shayar da danshi a cikin

lalace (delaminated) yanki a PCB.

A cikin sassan da ke gaba, hanyoyin da ake amfani da su don tantancewa

mafi ƙanƙanta da matsakaicin ƙarfin tuntuɓar juna.

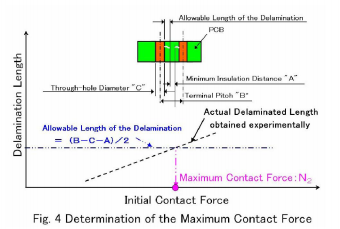

D. Matsakaicin Ƙaddamar Ƙarfin tuntuɓar

Yana yiwuwa cewa interlaminar delaminations a cikin PCB jawo

ragewar juriya na rufi a babban zafin jiki da kuma cikin

yanayi mai danshi lokacin da aka sami karfin lamba da yawa.

wanda aka haifar da haɗuwa da matsakaicin matsakaici

girman tasha da mafi ƙarancin diamita ta rami.

A cikin wannan ci gaban, matsakaicin ƙarfin lamba da aka yarda

an samu kamar haka;(1) ƙimar gwaji na

mafi ƙanƙantar nisan insula "A" a cikin PCB ya kasance

samu da gwaji a gaba, (2) halal

An ƙididdige tsawon delamination ta hanyar geometrically kamar (BC A)/2, inda "B" da "C" su ne filin tasha kuma

diamita ta rami bi da bi, (3) ainihin delamination

tsayi a PCB don nau'ikan diamita na ramuka ya kasance

samu ta hanyar gwaji kuma an tsara shi akan tsayin da aka yanke

vs. zanen ƙarfin tuntuɓar farko, kamar yadda aka nuna a hoto na 4

schematically.

A ƙarshe, an ƙayyade iyakar ƙarfin tuntuɓar don haka

don kada ya wuce adadin da aka yarda da shi na delamination.

Hanyar kiyasin sojojin tuntuɓar iri ɗaya ce da

ya bayyana a sashin da ya gabata.

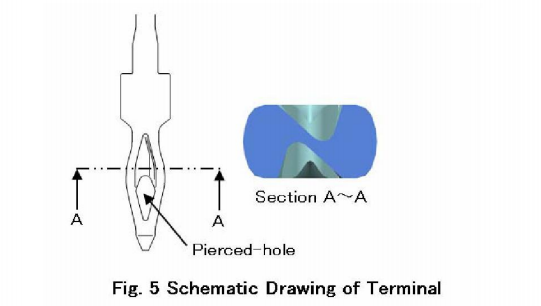

E. Tsarin Siffar Tasha

An ƙera siffa ta ƙarshe ta yadda za a iya samarwa

karfin tuntuɓar da ya dace (N1 zuwa N2) a cikin ramin da aka tsara

kewayon diamita ta amfani da sassa uku masu iyaka

hanyoyin (FEM), ciki har da tasirin pre-plastic nakasar

inducing a masana'antu.

Saboda haka, mun ɗauki tasha, mai siffa kamar an

"N-siffar giciye sashe" tsakanin wuraren tuntuɓar kusa da

kasa, wanda ya haifar da karfin tuntuɓar kusan iri ɗaya

a cikin kewayon diamita ta hanyar-rami, tare da a

huda-rami kusa da tip kyale lalacewar PCB zama

rage (Fig. 5).

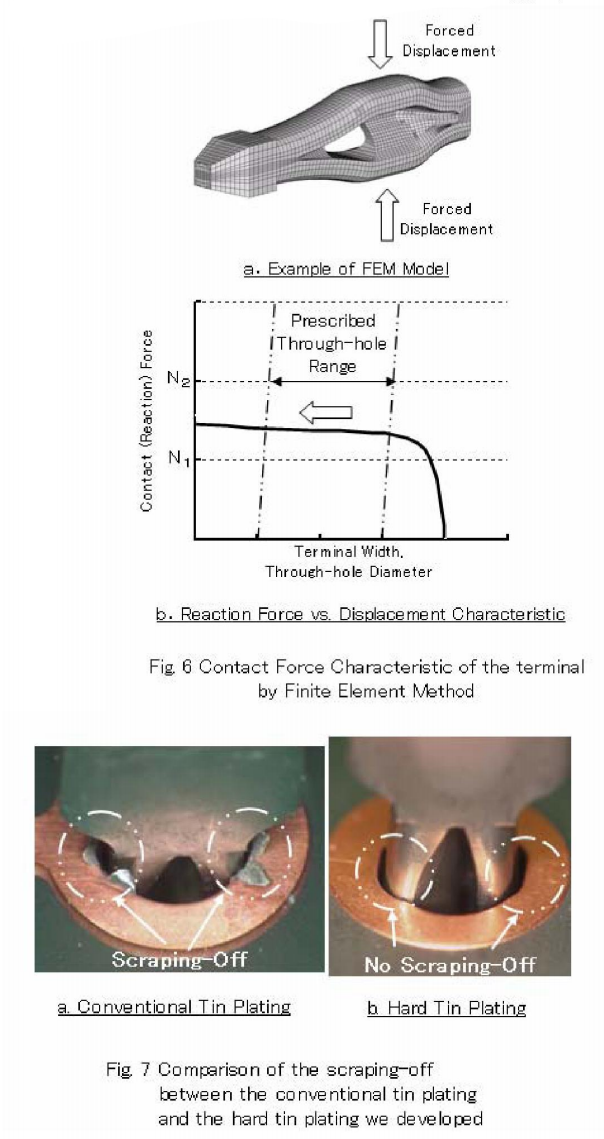

An nuna a hoto na 6 misali ne na mai girma uku

Samfurin FEM da ƙarfin amsawa (watau ƙarfin lamba) vs. da

zanen ƙaura da aka samu ta nazari.

F. Haɓaka Ƙunƙarar Tin Plating

Akwai daban-daban surface jiyya ga hana

oxidization na Cu akan PCB, kamar yadda aka bayyana a II - B.

A cikin yanayin jiyya na ƙarfe plating saman, kamar

tin ko azurfa, amincin haɗin lantarki na latsa-fit

ana iya tabbatar da fasaha ta hanyar haɗuwa tare da

na al'ada Ni plating tashoshi.Duk da haka a cikin yanayin OSP,tin plating a kan tashoshi dole ne a yi amfani da su don tabbatar da dadewaamincin haɗin wutar lantarki na lokaci.

Koyaya, tin na al'ada akan tashoshi (don

misali, na 1ltm kauri) yana haifar da gogewana tina lokacin aiwatar da shigarwar tasha.(Hoto. "a" a cikin hoto na 7)

kuma wannan scraping-off mai yiwuwa haifar da gajerun hanyoyin dam tashoshi.

Don haka mun samar da sabon nau'in kwano mai wuya

plating, wanda baya haifar da wani tin da ake goge-kashe dawanda ke tabbatar da amincin haɗin wutar lantarki na dogon lokacilokaci guda.

Wannan sabon tsari na plating ya ƙunshi (1) ƙarin siraren gwangwani

plating a kan underplating, (2) dumama (tin-reflow) tsari,

wanda Forms da wuya karfe gami Layer tsakanin

underplating da kwano plating.

Domin karshen abin da ya rage na tin plating, wanda shi ne sanadi

na scraping-off, a kan tashoshi ya zama musamman bakin ciki da kuma

yana rarraba ba daidai ba a kan alloy Layer, babu goge-kashenaan tabbatar da tin yayin aiwatar da shigarwa (Hoto "b" inHoto 7).

Lokacin aikawa: Dec-08-2022

Youtube

Youtube