Bukatar Haɗin Haɗin Solder Marasa Aiki Akan Shirye

Ƙirƙirar hanyoyin haɗin haɗin kan- jirgi yanki ne na gagarumin ƙalubale don aiwatar da hanyoyin siyar da dalma maras gubar.Ɗayan maɓalli ɗaya don masana'antun ƙara girma shine kiyaye ingantaccen samarwa gabaɗaya.Hanyoyin siyar da siyar da na biyu waɗanda a al'adance ake buƙata don haɗa manyan haɗe-haɗe da sauran haɗe-haɗe na musamman suna da matukar wahala a juye zuwa matakai marasa gubar.Wannan yana da ƙalubale musamman ga PCBs masu nauyi na jan ƙarfe kamar haɗin haɗin wutar lantarki.

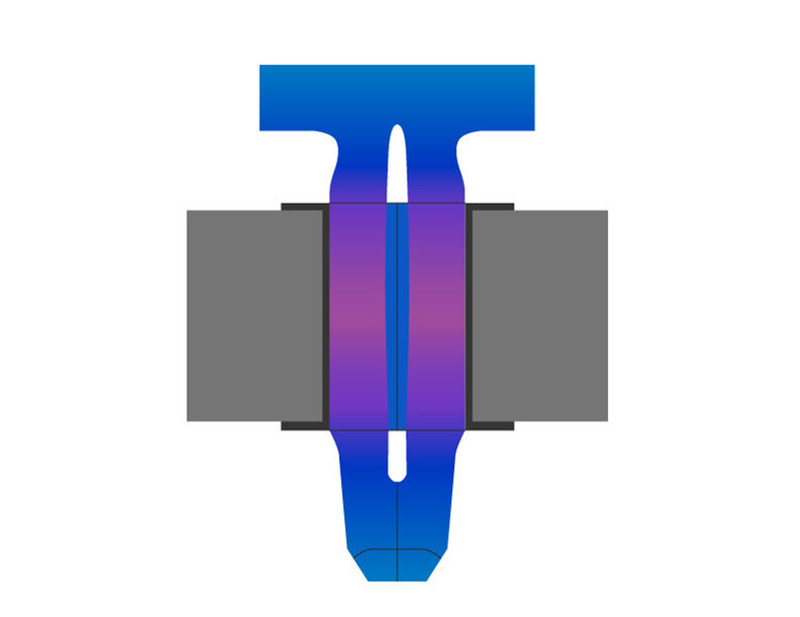

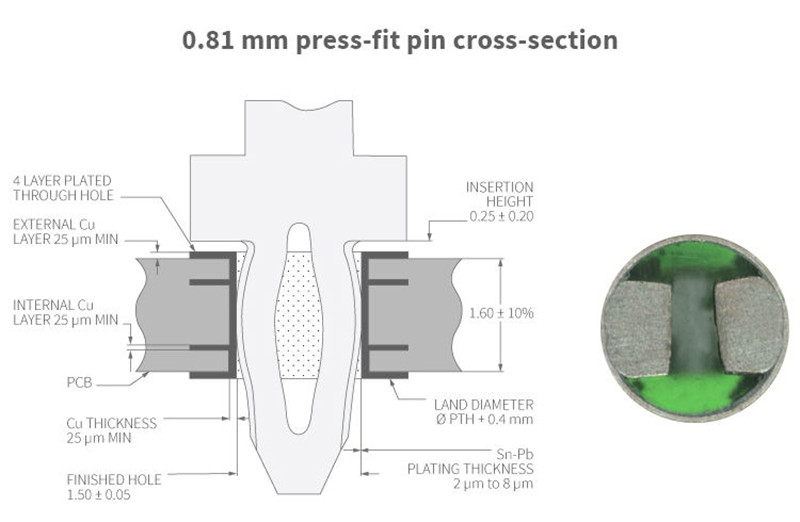

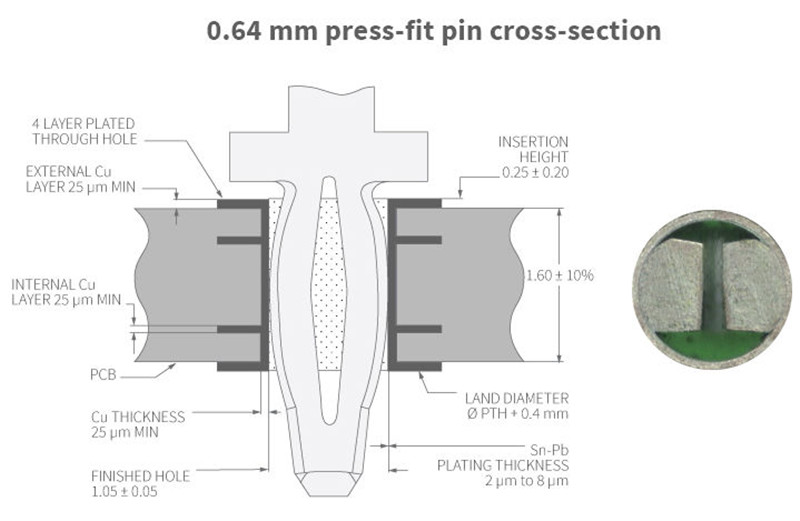

Fitin latsa-fit (mai yarda) ya kasance sama da shekaru 20, tare da amfani da yawa a kasuwanni da aka yi niyya da yawa.Latsa-fit (mai yarda) fasaha ya haɗa da ƙira ta musamman na sashin shigarwa na kowane fil, wanda ke ba da ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan iskar gas tare da ramin da aka yi da shi kuma baya buƙatar kowane matakin siyarwa na gaba.

Sashin saka fil ɗin ya fi girma fiye da diamita na ramin amma an tsara shi don lalacewa yayin sakawa, wanda ke haifar da ƙaƙƙarfan juzu'i tsakanin fil da filin da aka zana.

Tsarin Idon-da-Needle

A cikin shekaru da yawa, an yi amfani da hanyoyi daban-daban na ƙira don samar da abin da ya dace don dacewa da fil.Kamar yadda fasahar latsa-fit (mai yarda) ke motsawa zuwa sabbin aikace-aikace kamar Akwatunan Junction Smart, a cikin masana'antar kera motoci, yana da mahimmanci cewa ƙarfin da ke tsakanin fil da saman da aka yi da shi ya kasance mai isa don jure yanayin muhalli da abubuwan injiniya kamar zafi, zafi, girgiza, girgiza da sauran rugujewar yanayi waɗanda ke cikin yanayin mota.

Hanyar "ido-na-allura" an tabbatar da ita don samar da fasahar da ta fi dacewa don inganta ƙarfin farko da kuma ci gaba.Zane-zane irin na bazara da aka yi amfani da shi a cikin daidaitawar ido-na allura yana ba da ƙarfin tuntuɓar dogon lokaci a kan ganga na rami.

Yanayin zafin aiki don duk fil shine -40 zuwa 125 C, kuma suna iya jure wa 125 C na awa 1,008.Hakanan ana samun fil masu kusurwa-dama (jeri ɗaya da biyu) don haɗa PCBs daidai gwargwado.Ana ba da duk samfuran tare da plating mara gubar RoHS.

An ƙera masu haɗin haɗin gwiwa da filastik mai ɗorewa tare da faffadan fil.Suna iya ƙunsar kusan fil uku, kuma masu yawa kamar 256.”: Majami'ar Majalisar ta ce a cikin labarinta game da haɗin haɗin yanar gizon Press-fit da fa'idodinsu.

Ƙarfin ɗaukan Yanzu

Latsa-fit (mai yarda) tashoshi suna da kyakkyawan ƙarfin halin yanzu kuma suna iya taimakawa musamman don haɗin wutar lantarki akan allunan tagulla masu nauyi, waɗanda ke da wahalar siyarwa don haka sun fi wahalar canzawa zuwa wuraren da ba su da gubar.Maimakon ciwon zuwa tweak ko daidaita reflow sigogi sigogi don saduwa da musamman soldering kalubale ga nauyi tagulla PCBs, masana'antun iya kafa in mun gwada da fadi da al'ada tsari kula windows da kuma kawar da musamman soldering bukatun ta amfani da yarda interconnects ga high-yanayin aikace-aikace.

An gwada don Amincewa, Ƙarfin Riƙewa & Juriya na Muhalli

Nau'in fasahar da aka gwada-na-da-allura Press-fit (masu yarda) an gwada su sosai don tabbatar da bin manyan buƙatun masana'antu, gami da SAE/USCAR-2, Rev4, EIA Publication 364 da ƙayyadaddun IEC 60352-5.Tsarin gwaji ya yi amfani da tsarin ƙima na muhalli, inji da abubuwan dogaro a ƙarƙashin yanayin sarrafawa.

An gudanar da gwaje-gwaje don kewayon hanyoyin haɗin gwiwar Latsa-fit (mai yarda) daban-daban da nau'ikan PCB (ciki har da platin jan karfe, plating na zinariya da gama HASL).Dukkan samfuran gwaji an ƙirƙira su kuma an haɗa su ta amfani da dabarun samarwa na yau da kullun da ƙa'idodi masu inganci.

Ƙwararren gwaji ya haɗa da rawar jiki, girgiza zafin zafi & rayuwa mai zafi, girgiza injina, ƙarfin sakawa, ƙarfin riƙewa, zafi, hawan keke na yanzu da juriyar lamba.Duk ƙirar haɗin haɗin gwiwar sun ci gaba da wucewa ba tare da lalacewa da/ko daidaituwa tare da takamaiman sigogi ba.

Ƙayyadaddun Ƙididdiga na Fin, Tsare-tsare, Zaɓuɓɓuka

Latsa-fit (mai yarda) haɗin haɗin haɗin gwiwa yana samuwa a halin yanzu a cikin saitunan masu zuwa:

Tashoshi masu hankali (magudanar ruwa, shafuka, da sauransu)

Fil masu ci gaba

Latsa-fit kan kai a kan ci gaba da reels ko tsayin da aka yanke (ɗaya-biyu ko biyu-by)

Square ko zagaye (misali masana'antu ko diamita na al'ada & tsayin fil)

Lokacin aikawa: Juni-22-2022

Youtube

Youtube