A.Duk da cewa Sumitomo Wiring Systems, Ltd. ya riga ya samar da "Farkon Generation Press-Fit Connector" ga abokin ciniki na Turai daga 2004, yana da iyaka ta hanyar juzu'in diamita na rami na 90ptm kawai kuma wannan shine babban dalilin wahala. tallafi ga sauran abokan ciniki da yawa, gami da na gida.

Don haka mun fara haɓaka "Maɗaukakin Latsa-Fit Connector na Biyu", wanda ya kasance mai daidaitawa zuwa kewayon jurewar diamita mai faɗi, cikin sa ran kasuwa mafi girma a nan gaba.

B.Aikace-aikace don Haɗin Mota Don aikace-aikacen fasahar haɗin latsa-fit zuwa masu haɗin mota, dole ne mu yi la'akari da wasu takamaiman dalilai, kamar yadda aka jera a ƙasa.

(1) Dogarowar Haɗin Haɗin Tsayi a cikin mafi tsananin yanayin muhalli da ake buƙata don masu haɗin mota.

(2) Ƙananan Farashin, aƙalla daidai da na tsarin siyar da kwararar kwararar ruwa.

(3) Daidaitawa zuwa fiɗaɗɗen juriyar jurewar diamita ta rami.

(4) Amincewa da haɗin kai don jiyya na PCB daban-daban.

Bayanin (4) yana nufin cewa jiyya daban-daban, kamar "Immersion Plating (tin ko azurfa)" da "Organic Solderability Preservative (OSP)" an haɓaka kwanan nan kuma an karɓa don hana oxidization na saman jan karfe akan PCB a matsayin madadin HASL na al'ada. (Hot Air Solder Leveling) [2] .Duk da haka, waɗannan jiyya na saman na iya shafar amincin haɗin haɗin latsa-fit, saboda jiyya a kan PCB sun shiga cikin hulɗar kai tsaye tare da tashoshi.

II.KYAUTATA JAGORA

A. Takaitaccen Bayani

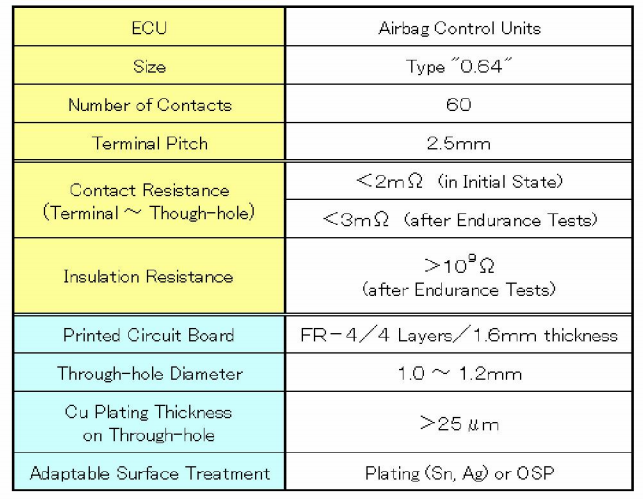

Ƙayyadaddun mahaɗan latsa-fit da muka haɓaka shinetaƙaice a cikin Table II.

A cikin Table II, "Girman" yana nufin faɗin lamba na namiji (wanda ake kira "Girman Tab") a mm.

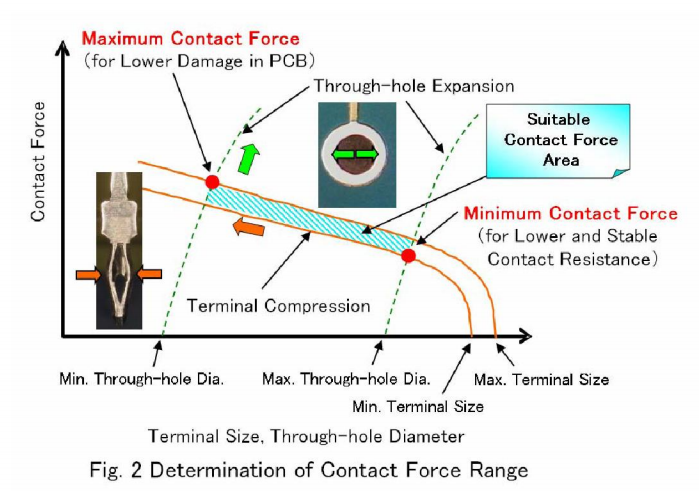

B.Madaidaicin Ƙaddamar Ƙarfin Tuntuɓar ƘaddamarwaA matsayin mataki na farko na ƙirar tasha-fit, dole ne muƙayyade iyakar ƙarfin lamba da ya dace.

A saboda wannan dalili, nakasawa halayen zane-zane naAna zana tashoshi da ramuka cikin tsari, kamar yadda aka nunaa cikin siffa 2. An nuna cewa dakarun tuntuɓar suna cikin axis a tsaye,yayin da m girma da kuma ta-rami diamita ne a cikinaxis a kwance bi da bi.

Layuka biyu don nakasar tasha suna nufin waɗanda suke don matsakaicin matsakaicin matsakaicin matsakaici da mafi ƙarancin ƙima saboda tarwatsewa a tsarin masana'anta bi da bi.

Tebura II Scecification na Haɗin da muka haɓaka

A bayyane yake cewa ƙarfin hulɗar da aka samar tsakanin tashoshi da ko da yake-ramuka ana ba da shi ta hanyar haɗin kai na zane-zane guda biyu don tashoshi da ramuka a cikin siffa 2, wanda ke nufin daidaitaccen yanayin matsawa ta ƙarshe kuma ta hanyar fadada rami.

Mun ƙaddara

(1) mafi ƙarancin ƙarfin lamba da ake buƙata don yin juriya na lamba tsakanin tashoshi da ko da yake-ramuka ƙasa da kwanciyar hankali kafin / bayan gwaje-gwajen jimiri don haɗuwa da mafi ƙarancin ƙima da matsakaicin diamita ta rami, da (2) matsakaicin ƙarfi. isa don tabbatar da juriya na rufin tsakanin ramukan da ke kusa da su ya wuce ƙayyadaddun ƙimar (109Q don wannan haɓakawa) bin gwaje-gwajen jimiri don haɗuwa da matsakaicin matsakaicin matsakaicin girma da mafi ƙarancin diamita ta rami, inda lalacewar juriya ta lalacewa ta haifar da danshi. tsomawa cikin yankin da aka lalace (delaminated) a cikin PCB.

A cikin sassan da ke gaba, hanyoyin da ake amfani da su don tantance mafi ƙanƙanta da matsakaicin ƙarfin tuntuɓar juna.

Lokacin aikawa: Dec-07-2022

Youtube

Youtube